Machinery

Rimex Metals Group is able to provide a vast array of high-quality, dynamic specialised finishes on stainless steel and other metals.

Having been established for over 60 years, we have gained a long-standing reputation in the metal finishing industry.

Rimex provides metals to keep the production line rolling.

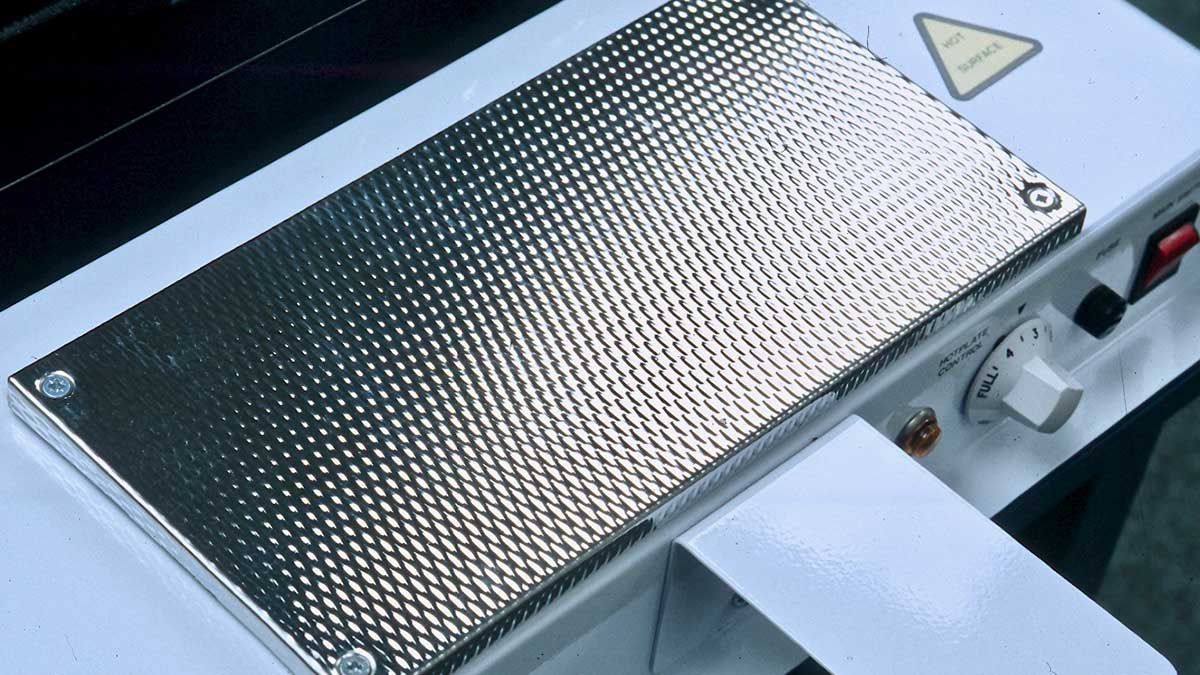

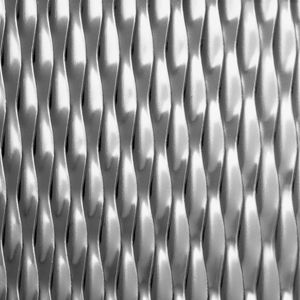

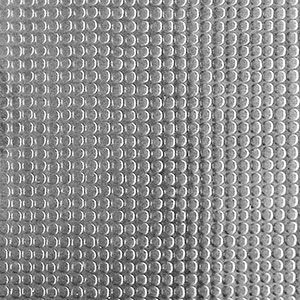

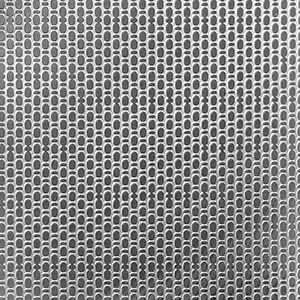

From vegetables to nuts and bolts, glass bottles to confectionery and pharmaceuticals, we have a patterned stainless-steel metal finish to keep your production line moving and your bottom line healthy. Unlike flat metals such as satin or #4 polished stainless steel, our optimal patterned designs on stainless-steel, helped by the ‘peak’ of the pattern keeps friction to a minimum.

Machinery Product Benefits

-

Reduced friction and enhanced product flow.

-

Highly resistant to impact damage and scratching.

-

Stainless steel has a long lifespan.

-

Aesthetically pleasing state-of-the-art finishes.

-

High manufacturing performance.

-

Highly hygienic.

-

Excellent fire performance and safety.

-

Patterned finishes are extremely durable.

-

Stainless steel is an inherently green product.

Our patterned stainless-steel finishes are known to not only be extremely durable but also easy-to-clean.

When used for machinery cladding and as protection for areas prone to impact, you can definitely benefit from the high quality metals that Rimex offers, and as a result also reduce your long-term maintenance costs.

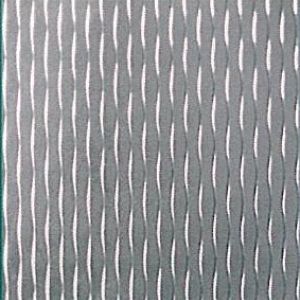

Other known uses for our products including more subtle patterns from our Onetex™ range have included cashpoint dispenser machines, forecourt petrol pumps to checkout tills as our products offer durability, aesthetics and performance in heavy usage environments.

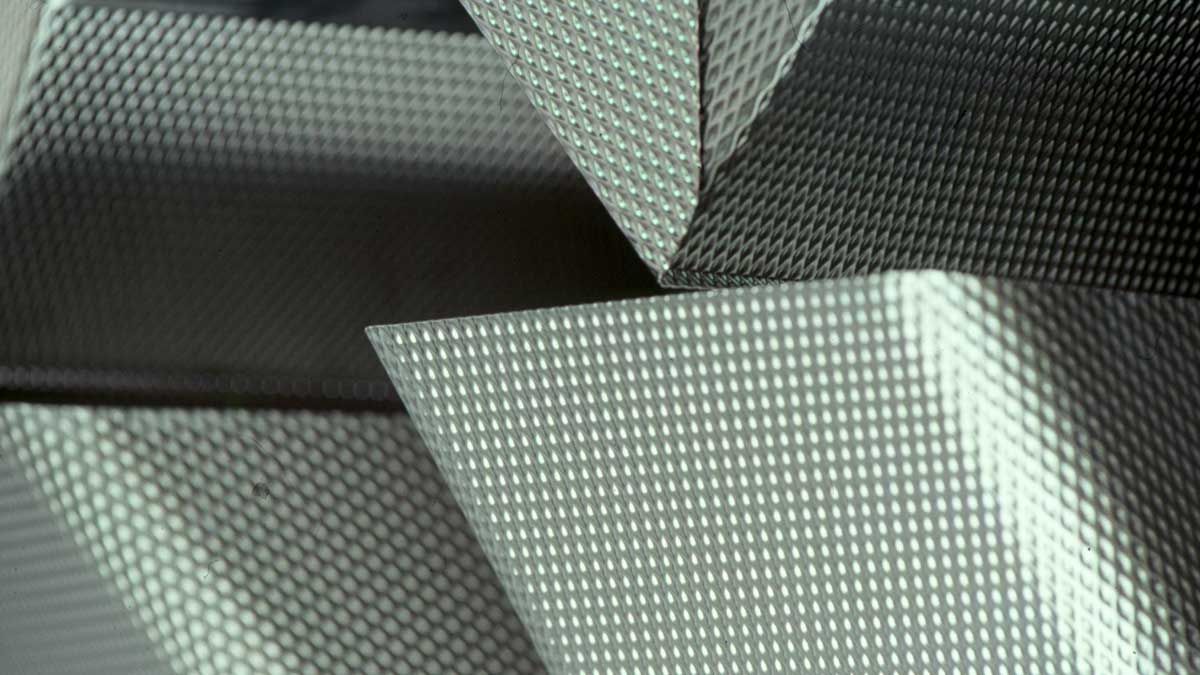

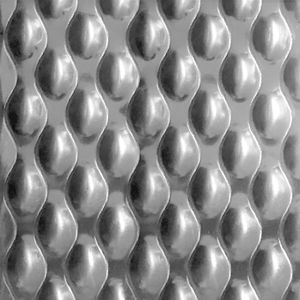

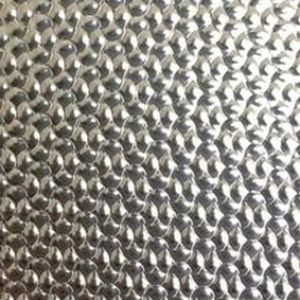

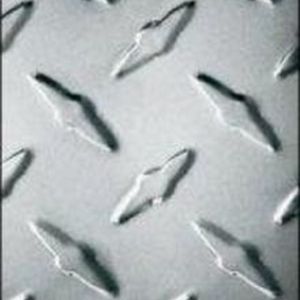

Rimex’s MaxiSlideTM Collection

Rimex’s MaxiSlideTM Collection of metal finishes can be fabricated to form any parts for processing machinery to quicken the flow of goods through a production line.

The Patterned Finishes are manufactured by cold rolling various metals in sheet and coil format. The patterned product is then levelled and processed for flatness.

From food products to industrial components which are more rapidly and efficiently moved down conveyors, the entire production process downtime is greatly reduced, thereby increasing profit margins. The processing of wet materials in particular is also greatly enhanced.